MRO Middle East & AIME

Aviation Week Network’s MRO Middle East (#MROME), co-located with Aircraft Interiors Middle East (AIME), will be held 8-9 February in Dubai, UAE at the Dubai World Trade Center.

JDA & WMG, University of Warwick Study

European manufacturers are failing to effectively use data and analytics when it comes to supply chain planning and segmentation, according to a new report from JDA Software Group, Inc., and WMG, at the University of Warwick.

Embracing Technology: Four Trends for Manufacturing Marketers That Will Drive Growth

EME Outlook takes a look at the technological breakthroughs destined to have the biggest impact on business growth and the sales pipeline.

Emirates Metallic Industries Company (EMIC)

Emirates Metallic Industries Company Ltd (EMIC) is poised to reinvest in a new facility and two new production lines via its latest expansion strategy.

Sheet Metal Working Technology Exhibition : The New Generation

From 25-29 October, 2016, the 24th International Sheet Metal Working Technology Exhibition will open its doors again in Hannover, Germany.

MRO Europe

Penton’s Aviation Week Network’s MRO Europe (#MROE) will be held from 18-20 October at the RAI in Amsterdam.

EuroBLECH Presents 2016 Online Competition

After the great success of the first online competition in 2014, EuroBLECH 2016 is once again presenting running an online competition: “The New Generation of Sheet Metal Working”.

Italian Packaging Machinery: 2015 Turnover Close-to 6.2 Billion Euros

The Italian packaging machinery industry is made up of 588 companies employing 27,906 people and generating a turnover of 6,197 million euros.

Building a Future as Strong as Steel in Europe

The steel manufacturing industry in Europe has long been one of the main economic drivers contributing to growth, employment and fostering innovation across the Member States.

Matrix Composites and Engineering : Engineering Innovators

Having gained significant brand awareness, Matrix Composites & Engineering has taken many opportunities to secure the Company’s longevity.

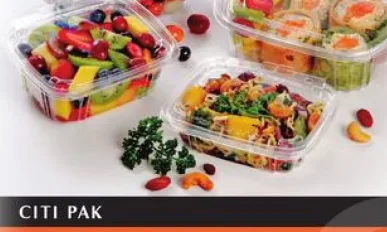

Citi PAK : A Brand Loyalty Success Story

Citi PAK has built its brand loyalty over the past eight years based on strong and continuing international relationships which are directly contributing to the Company’s newfound growth strategy.

Lucky Group : Celebrating a Remarkable Journey

With a policy of Kaizen in place across all of its frontiers, Lucky Group, one of the largest secondary metal recyclers in the Middle East, continues to preserve its home-grown values of credibility, quality and personal service, while delivering products and services that surpass the industry norm.