Equipped with the steadfast mantra of ‘don’t send a man to do a machine’s job’, we learn about DOK-ING’s comprehensive and transformative robotics solutions that are saving countless lives and evolving industries throughout Europe. The company’s leadership team across its three divisions tell us more.

ROBOTICS THAT SAVE LIVES

Leading the charge in heavy-duty robotics and autonomous systems, DOK-ING has established itself as a manufacturing powerhouse, globally renowned for producing world-class unmanned vehicles that protect human lives in otherwise hazardous and harmful environments.

Headquartered in Zagreb, Croatia, the company operates across 40 countries and diligently meets the needs of the security and defence, underground mining, and energy sectors through three proactive divisions.

DOK-ING strives to produce forward-thinking applications that deliver a step-change in both safety and efficiency.

Indeed, the company first emerged from the mission to find a mechanical solution to take humans away from dangerous and labour-intensive environments during the demining effort in Croatia in the early 1990s.

Since then, DOK-ING’s focus has remained on operating in hazardous and dangerous areas where conventional first responders are incredibly limited, particularly in the extreme conditions often experienced in the military and during underground mining.

“The technology already exists, but at DOK-ING, we’ve made a deliberate choice to apply it where it matters most – in the world’s most dangerous and demanding jobs,” introduces Davor Petek, COO of DOK-ING Security and Defence.

“By targeting high-risk environments, we create real impact, reducing exposure for frontline workers whilst improving operational performance. This is where innovation truly proves its worth, and it’s the path we’ve committed to,” echoes Luka Petro, COO of DOK-ING Mining.

“Bottom line, our systems are designed to thrive where humans would otherwise die,” Petek adds.

DELIVERING THE COMPLEX NEEDS OF DEFENCE

As one of the company’s key focus divisions, DOK-ING Security and Defence delivers critical unmanned systems for the harshest military situations.

Due to ongoing political conflicts across Europe and further afield, alongside the rise of chemical, biological, radiological, and nuclear (CBRN) environments, the division’s unmatched capabilities are at the top of development and procurement priority lists due to an increasingly complex global security situation.

Croatia’s defence capabilities in particular are shifting into a higher gear, as demonstrated by the recent establishment of an inter-ministerial commission for the nation’s defence capabilities and industry development, paving the way for improvements in business-to-government (B2G) activities.

However, it will still be some time before the appropriate policies and initiatives are fully operationalised to effectively close Croatia’s capability gap when compared to other European countries.

“The financial aspect is there and our production capacity is increasing, but without long-term contracts and orders from governments, industry cannot close the gap,” Petek discusses.

“We also still have a very slow and complex procurement process that was maybe acceptable in peace time, but we are now operating in a different, more demanding environment that requires a serious change in EU procurement policies.”

This is particularly pertinent given the recent conflict between Russia and Ukraine, which has increased the significance of secure defence capabilities.

With this in mind, DOK-ING Security and Defence’s advanced systems designed for mobility operations and demining and humanitarian demining, such as the MV-4 Scorpion and MV-10 Bison, are preferred systems in Ukraine due to their high survivability and reliability.

The continual targeting of the country’s critical infrastructure has also highlighted the demand for the division’s crisis response systems, including the MV-3 Hystrix, MV-5 Tusk, and MV-8 Komodo (Komodo) CBRN.

A NEXT-GENERATION UNMANNED PLATFORM

As DOK-ING Security and Defence’s latest modular platform, the Komodo is proving to be a critical capability for the increasing operational use of unmanned vehicles.

“When we designed the Komodo, we had one goal in mind: to increase efficiency and reduce costs for the end user whilst maintaining the same – or similar – level of capability, all with a strong focus on protecting human lives and property. I truly believed we have succeeded in that mission,” Petek states.

Therefore, as unmanned ground vehicles continue to be integrated into the capabilities of military forces, the Komodo aims to provide the same levels of combat support as manned vehicles.

“Combining manned and unmanned platforms with same or mutually supporting capabilities increases combat power and force protection whilst ultimately lowering cost,” Petek explains.

Given the Komodo is a payload-agnostic platform, its users are able to integrate payloads that are either lacking on conventional platforms or more efficient and acceptable due to unmanned aspects.

Furthermore, providing a single platform with multiple payloads simplifies operations, maintenance, and logistics support, enabling users to utilise the same platform with combined capabilities for multiple tasks.

As such, the Komodo provides immeasurable benefits to ongoing conflicts, offering versatility in response to threats and a vast range of payload capabilities. This is particularly advantageous given the current combat systems in service are either outdated, very expensive, or there are too few pieces of equipment for it to be considered for expansion.

“We aim to tackle these challenges but in the unmanned vehicle domain. We plan to roll out unmanned and programable systems for both hasty and planned counter mobility operations.

“At the same time, we will provide solutions for mobility operations that are currently only available on manned platforms,” Petek sets out.

Elsewhere, DOK-ING Security and Defence is heavily involved in EU and NATO technology development projects that define current and future industry trends, from critical infrastructure protection to a varied defence portfolio.

For example, the EU has recently focused on the development of robotic systems and capabilities that support the civilian structures responsible for critical infrastructure protection and response operations.

DOK-ING Security and Defence’s unmanned support to first responder units aligns with this goal and ensures the division is well positioned to provide innovative solutions that not only support these units but drastically increase their response capabilities.

“When we designed the Komodo, we had one goal in mind: to increase efficiency and reduce costs for the end user”

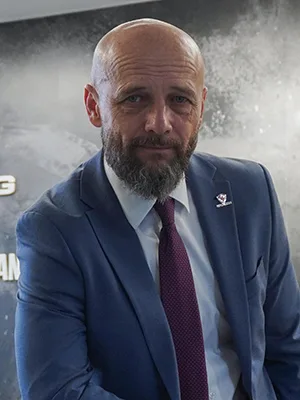

Davor Petek, COO, DOK-ING Security and Defence

BREAKING THE MINING PARADIGM

DOK-ING’s reputable capabilities also extend to its mining division, which has pioneered a state-of-the-art fleet of narrow reef equipment (NRE) for the South African and global underground mining market.

The narrow reef mining sector has undergone significant challenges in the last 20 years, as businesses have had to choose between limited methods, including more conventional and labour-intensive methods that are difficult to scale in a cost-effective manner and have significant safety risks, and low-profile mechanisation that often leads to dilution, high costs, and limited adaptability to changing reef inclinations.

“With the development of the NRE fleet, we’re breaking that paradigm and delivering a solution that enables the safe, efficient, and truly scalable mechanisation of narrow reef production,” excites Petro.

“This isn’t just an incremental improvement – it’s a game-changer for sub-horizontal, thin orebodies like those found in South Africa’s platinum group metals and gold sectors. It’s a bold step towards unlocking value that was previously trapped by outdated methods.”

DOK-ING Mining’s NRE fleet stands out in particular due to its facilitation of mechanised mining in ultra-narrow reefs of below 1.7 metres.

Furthermore, the fleet has continually demonstrated it can consistently achieve optimum performance, be maintained effectively, and deliver the required output, thus shifting the industry’s response to the equipment from cautious interest to genuine enthusiasm.

This is evidenced by DOK-ING Mining’s recent application of its NRE for Bokoni Platinum Mines, which demonstrated the extent to which the fleet can consistently meet production targets, thus representing the future of narrow reef mining.

“This success gave us the confidence to scale our NRE to the global stage,” Petro prides.

With recognition and support from EIT Rawmaterials, a consortium in the European raw materials market, DOK-ING Mining’s NRE fleet is on an accelerated path and poised to become the global benchmark in mechanised mining.

“What began as a bold idea is now setting the standard for what’s possible in some of the world’s most challenging underground environments,” he insights.

“By targeting high-risk environments, we create real impact, reducing exposure for frontline workers whilst improving operational performance. This is where innovation truly proves its worth, and it’s the path we’ve committed to”

Luka Petro, COO, DOK-ING Mining

GURANTEEING CONTINUOUS SAFETY

DOK-ING Mining further stands out due to the plethora of safety benefits that its robotic systems provide, primarily due to the introduction of remotely operated machines that have transformed what was once a highly hazardous environment.

Using NRE technology not only removes personnel from dangerous to supported environments but also allows the operator to achieve the same output as a dozen miners at the face, without being exposed to the risks.

DOK-ING’s ultra low-profile Dozer, for instance, addresses one of the most pressing safety challenges in narrow reef mining – replacing the scraper winch, which historically results in many injuries and fatalities.

More than a mechanical upgrade, this equipment represents a step-change in how safety and productivity can co-exist.

“Even in the best-run operations, underground working conditions remain extreme – that’s why the shift to electric machinery is so critical. It’s not just about reducing toxic fumes and noise levels, but cutting the cost and complexity of ventilation infrastructure,” Petro highlights.

No longer viewed as a mechanism of the future, electric machinery in mining is already proving to be smarter, more reliable, efficient, and eco-friendly.

Accordingly, the division’s NRE fleet is fully electric and emission-free, indicating an industry-wide departure from diesel-based equipment.

“I firmly believe it is only a matter of time before electric becomes the standard and not the alternative. The mine offers a perfect environment to accelerate this transition,” Petro asserts.

Indeed, a mine site provides a long-term construction site with fixed infrastructure which is ideally suited for electric heavy machinery.

“It’s a natural symbiosis – the mine needs cleaner, quieter, smarter tools, and electric technology needs a proving ground. This is where innovation meets opportunity, and transformation becomes inevitable,” he expands.

As part of the development of its remote-controlled technology, DOK-ING Mining is taking the next step towards teleoperation and semi-autonomous systems in order to achieve its ultimate goal of zero personnel underground.

Although this is a unanimous vision across the industry, the division is dedicated to leading the way by pushing boundaries with further automation.

“It won’t happen overnight, but with each innovation, we move closer to a safer, smarter, and fully mechanised future; just as we’ve done so far, we’re ready to keep leading that journey.”

SET FOR MINING EXPANSION

Equipped with a steadfast mission, DOK-ING Mining is now recognised as a leader in innovative ultra-low and extra-low profile mining solutions, expanding the division’s presence rapidly across the globe.

With its eyes set on South America as a new frontier and its extra low-profile technology gaining traction in Canada, DOK-ING Mining’s solutions are ready to deliver on the complex demands of international mining markets.

Such targets will be reached by staying true to its founding mission, expanding its product portfolio, and delivering new technologies designed specifically for the world’s hardest-to-access ore bodies.

“R&D has always been at the core of DOK-ING, and we’re committed to carrying that legacy forward by pushing the boundaries of what’s possible, one breakthrough at a time,” Petro states.

As such, DOK-ING Mining is building a future where mining is no longer seen as dangerous or outdated, but as a space of innovation, safety, and high efficiency.

OVERCOMING ENERGY OBSTACLES

Another subsidiary of the organisation, DOK-ING Energo endeavours to tackle Europe’s energy and waste challenges.

The division’s initial focus revolved around helping cities solve their waste management problems. However, as the use of hydrogen gained prominence, DOK-ING Energo broadened its approach to cater to industry evolutions.

Case in point, the EU is working hard to accelerate its hydrogen economy, facilitating strong research networks, funding programmes, and ambitious climate targets.

A number of industry-wide steps are needed to develop this further, such as a robust market network, clear regulations, targeted incentives, and strategic support for small to medium-sized enterprises.

Croatia specifically requires greater cooperation between industry, academia, and policymakers if its hydrogen use is to take centre stage.

Although the nation’s regulatory framework for such is still being developed – creating market uncertainty – platforms including the Croatian Chamber of Commerce’s Croatian Hydrogen Group indicate a domestic hydrogen ecosystem that can contribute meaningfully to the broader European strategy.

In light of this, DOK-ING Energo operates across both the energy and waste sectors in order to combat these adversities.

During the hydrogen production process, the division discovered a carbon-rich by-product of its system could be used in industries such as brick production, which improves the properties of bricks.

DOK-ING Energo has also developed water purification systems for water used in the Looper system – which converts non-recyclable waste into clean hydrogen – because it wants to follow circular economy principles in every aspect.

“Ultimately, we are working towards creating a system that can power itself, therefore contributing to its own energy self-sufficiency.

“This circular approach focuses on energy, waste, water, and materials, and is what sets us apart from other energy tech companies,” outlines Dr Danica Maljković, Head of Business Development at DOK-ING Energo.

“I believe our mix of engineering talent, dedicated R&D, and courage to develop what doesn’t yet exist will allow us to shape a more sustainable, circular, and resilient future – both in waste management and green energy production”

Dr Danica Maljković, Head of Business Development, DO-KING Energo

FACILITATING CLEAN ENERGY

A landmark technological innovation, DOK-ING Energo’s Looper system can process non-recyclable waste such as textiles and other contaminated organic matter through a thermochemical process that generates synthesis gas.

From this gas, the division extracts hydrogen whilst carbon from feedstock remains trapped in solid residue.

“As such, Looper is a unique technology because it simultaneously addresses two major global challenges – waste management and clean energy production,” Maljković voices.

During his recent visit to its facility, Wopke Hoekstra, European Commissioner for Climate, Net Zero, and Clean Growth, acknowledged the technology’s strategic value and praised its commercial and geopolitical potential in the energy sector.

“This kind of recognition is vital for us as it confirms Looper is not just a scientific innovation, but a technology with real market relevance and societal value,” she points out.

Indeed, the system’s modularity, mobility, and scalability make it highly appealing across multiple sectors. In fact, Looper offers a potentially more cost-effective alternative to hydrogen via electrolysis, particularly when waste reduction is taken into account.

DOK-ING Energo has already explored Looper’s implementation in waste management systems, wastewater treatment facilities, the textile industry, military camps, utility companies, airports, and remote locations, alongside many other uses.

“Basically, wherever people generate organic waste, which is nearly everywhere, Looper has the potential to be implemented.”

Notably, the technology also has the ability to create real societal impact, reflected in the Humana Nova cooperative in Čakovec, where Looper was deployed to convert textile waste for heating.

“This project was particularly meaningful because it showed how our technology could directly benefit vulnerable groups in society. It’s a powerful example of how innovation can serve environmental and social goals at the same time,” Maljković tells us.

FACILITATING CLEAN ENERGY

In the next five years, DOK-ING Energo strives to become a recognised name in Europe’s green transition, particularly in the field of waste to hydrogen process solutions.

“Our goal is to not only bring technologies like Looper to the market but also demonstrate that a company from Croatia can play a serious role in solving some of the world’s most complex environmental challenges,” Dr Maljković emphasizes.

The division is already experiencing an increased interest from international partners and institutions, which is essential for mutual learning, knowledge sharing, and global market visibility.

However, Maljković believes there is still room for the greater promotion of Croatian energy production across Europe.

“I believe our mix of engineering talent, dedicated R&D, and courage to develop what doesn’t yet exist will allow us to shape a more sustainable, circular, and resilient future – both in waste management and green energy production,” she concludes.

Equipped with a strong union of three powerful divisions, DOK-ING is ultimately set to achieve significant growth and become an international market leader in robotics and autonomous systems.

DOK-ING PARTNERS