Constellium has formed a partnership with STELIA Aerospace, a world major player in the design and production of aircraft equipped fuselages and CT INGENIERIE, a leading engineering company in technological innovation throughout the product lifecycle, to engage in a research and development project called FAST, focused on topological optimisation of aero structures and additive manufacturing, also known as 3D printing.

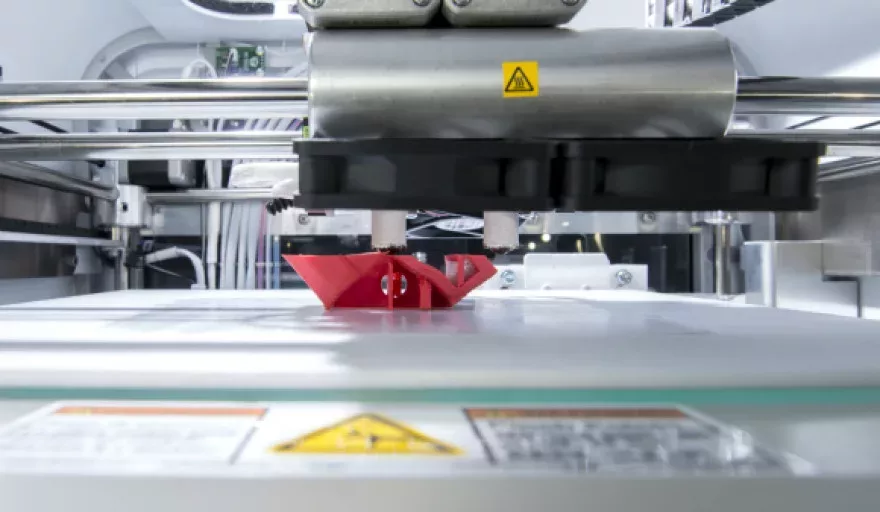

The FAST project is an innovative solution using optimised design and technologies to make large aerospace structures and parts more efficient, cost effective and inventive than ever before. 3D printing offers more alternatives for the design and production of large aerospace components, such as the fuselage. With the existing available technology, the design of large scale modules is currently limited due to cost, size and efficiency constraints. 3D fuselage printing has the potential to transform the aerospace industry, allowing for easy design modification, duplication and customisation at a lower cost.

“The goal of the FAST project is to change the way innovative technologies are implemented and to expand the usage of 3D printing. 3D printing will allow us to create metal shapes and properties that were previously impossible to produce,” said Bruno Chenal, Director of R&D, Constellium Research and Technology.

FAST is a long-term project that was formed last year and currently remains in early stages of development. Constellium will act as the primary material supplier, while STELIA Aerospace will lead the design and production efforts and CT INGENIERIE will optimise the design.

“We are excited to work with one of our customers, STELIA Aerospace, to find innovative alternatives for printing aluminium and developing aerospace technologies industry wide. This innovative process further supports Constellium’s commitment to work closely with all of our customers to develop customised solutions to meet their unique needs,” said Chenal.

3D printing is already used widely in technology and extrusion manufacturing, but what makes this project so unique is its unparalleled scale and the holistic optimisation approach.