Viru Keemia Grupp’s passion is for Estonia’s main natural resource – oil shale. Ahti Asmann, CEO and Chairman of the Management Board, elaborates on how the group is dedicated to the entire oil shale processing chain.

OIL SHALE FOR ESTONIA

Oil shale is a strategic energy resource in Estonia, where the industry is one of the most developed in the world.

Viru Keemia Grupp (VKG), Estonia’s largest private capital-based industrial group in the northeastern city of Kohtla-Järve, continues the tradition of adding value to oil shale processing, which was established in the Baltic state in 1924.

VKG combines this century of industrial tradition with the need to be internationally competitive in today’s constantly changing circumstances.

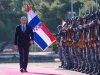

“Adding value to natural resources and secondary resources located in Estonia is our DNA,” prides Ahti Asmann, CEO and Chairman of the Management Board.

“Our aim – and an important consistent principle – is to add maximum value and length to the oil shale value chain. Today, VKG’s value chain is the longest in Estonia and one of the longest in the world.”

When Asmann received the proposal to lead VKG, the challenge was clear – to make a complex industrial enterprise more efficient and safer whilst taking it step by step towards new, more sustainable business areas.

This combination of actual economic impact and responsibility for Estonia’s energy security still keeps him in the field.

“I’ve been CEO of VKG since 2015, and I’m very happy that I’ve had the chance to work with topics that truly keep the economy running, including financing, infrastructure, and large industrial development projects,” he reflects.

“We are characterised by openness, dedication to our work, and constant development. We believe every step and activity must create greater value for everyone – our own people, our partners and clients, and the local community.”

TWO GREAT PILLARS

VKG’s activities are based on two great pillars, the first of which is shale oil production.

The group uses oil shale to produce liquid fuels and raw materials for the chemical industry.

Approximately 680,000 tonnes (t) of oil products are produced annually, with the main one being low-sulphur shale oil.

This is predominantly used as a component in ship fuel, but is also a good input for the chemical industry and can be used as fuel for industrial furnaces.

“We also produce oil shale gasoline and alkylresorcinol fractions which are used, for example, in the resin and rubber industries,” adds Asmann.

The second pillar is heat and electricity, which the group produces using the gases generated during oil production.

Heat is supplied to the local network area, whilst VKG’s electricity production usually covers a considerable part of Estonia’s total output.

“Our annual energy production is approximately one terawatt-hour,” Asmann confirms.

Whilst focusing on the production of shale oil, VKG also continues developing projects in areas such as the circular economy, renewable energy farms, and bioproducts.

“Our new business verticals support the principles of sustainability and help us to develop a futureproof and responsible enterprise,” he acknowledges.

“Adding value to natural resources and secondary resources located in Estonia is our DNA”

Ahti Asmann, CEO and Chairman of the Management Board, Viru Keemia Grupp

OIL SHALE SUPPLY

Oil shale excavation at VKG takes place at the Ojamaa mine, which opened in 2010 and was the most modern underground mine in Europe at the time.

Excavation takes place 30 to 60 metres underground, where the group extracts about six million t of mineral mass with conveyors straight to the enrichment plant and, from there, to the oil production plants.

“Just like oil production, mining takes place 24/7, which places high demands on the efficient logistical management of people and machinery and sets very strict requirements for environmental and work safety,” Asmann asserts.

“Things like hydrology, risk of collapse, sufficiency of ventilation, and dust generated during transportation are monitored daily.”

For a long time, the Ojamaa mine has been a stable supplier of raw material for VKG, but today, its resources are nearly depleted.

The group is therefore opening a new mine in the immediate vicinity, which will ensure the supply of oil shale for VKG until 2058.

On the other hand, it must also take EU climate policy developments into account and constantly assess the sector’s competitiveness in the framework of the EU Emissions Trading System (ETS).

“As it takes about five years from starting the mining operations to achieving full capacity, we have to be convinced that our company will remain competitive for at least 15 years to come,” emphasises Asmann.

VKG is investing up to €75 million in the new mine, including infrastructure, machinery, connections, and environmental protection solutions.

“The new mine is designed to meet today’s requirements – a well-planned extraction scheme, smart water management, minimal footprint aboveground, and maximum safety underground,” he informs us.

BIOPRODUCTS PLANT

Alongside its investment in the new mine, VKG is developing a bioproducts plant, a key project in the group’s shift from an oil shale-based industry to more sustainable production based on biomaterial.

Approximately half of Estonia is covered with forests, but the country lacked a proper pulp industry; pulpwood was mostly exported to Scandinavia without adding value to it.

“We found that VKG has the means, capital, and skills to enter the production of bioproducts and that our country needs this economic sector,” Asmann acknowledges.

In 2022, the group therefore launched preparations for a modern pulp mill project with an annual production capacity of nearly 500,000 t.

Several important interim goals were reached by VKG over the past year, whilst the local government has established a designated spatial plan.

This means the spatial solution is in place and the group can move forward with detailed design and construction preparations.

“We have entered into a long-term wood supply agreement with the State Forest Management Centre (SFMC), which will ensure a stable and sustainable raw material supply for the plant for 10 years after it starts operating,” confirms Asmann.

“The land necessary for the plant is also ensured. These three steps – planning, land, and raw material – are critical in every large-scale project.”

“The new mine is designed to meet today’s requirements – a well-planned extraction scheme, smart water management, minimal footprint aboveground, and maximum safety underground”

Ahti Asmann, CEO and Chairman of the Management Board, Viru Keemia Grupp

ECONOMIC AND ENERGY IMPACT

Importantly, VKG is not alone in supporting the project – the bulk of Estonia’s forest owners, the SFMC, and the Estonian Private Forest Union have all seen its potential to create a stable domestic output of pulpwood.

“In other words, we are not building a factory on account of forests but creating greater added value for wood within the existing allowed felling volumes,” Asmann explains.

The economic impact of the mill is clear, adding an estimated €500 million worth of value to the Estonian economy every year.

Moreover, it will create approximately 250 direct jobs and up to 1,000 indirect jobs in the supply chain and the service sector.

The mill will also be an important energy producer, generating more than 800 gigawatt hours (GWh) of green electricity a year and supplying heat to the local network.

“This will support Estonia’s energy security during a period when old production facilities are forced to be shut down but new ones have not yet been built,” outlines Asmann.

“The next big step is engaging a strategic partner; we have started negotiations with potential partners in cooperation with AFRY Capital, a leading adviser in the global pulp and bioindustry,” he reveals.

VKG’s message is simple – this is a project that clearly meets the unfulfilled demand in the market for adding value to pulpwood, aligns with Estonia’s climate goals and economic interests, and is welcomed by the Estonian government and local community.

“The latter is no longer elementary in today’s world.”

COMPETITIVE RENEWABLE POWER

In addition to the bioproducts plant, VKG is engaged in the development of wind, solar, and battery farms, particularly in the vicinity of its current production facilities, in order to find maximum synergies with existing production activities.

“Our aim is to add competitive renewable power to Estonia’s energy portfolio and use it to partly cover the industry’s own electricity needs,” Asmann sets out.

The projects are currently in the planning, environmental impact assessment, and network connection design phases.

VKG is working in cooperation with local governments, communities, and the system operator and plans to make the investment decision on a battery farm in Q1 2026.

In recent years, the group has consistently improved the energy efficiency of oil production.

At the same time, VKG is preparing a pilot project to explore post-incineration carbon capture from the flue gases of one of its Petroter plants.

The focus is on solutions that would be technically feasible considering the specifics of its moist flue gases whilst also being suitable for large-scale applications in the future.

“This supplements the incentives offered by the EU ETS and is a practical step towards reducing our footprint,” highlights Asmann.

Over the last two years, VKG seriously analysed the possibilities of chemically processing plastic waste.

It has abandoned the project for now due to the infancy of the technologies, however the circular economy sector remains of interest.

“We are not excluding the possibility of returning to the plastic waste project and are also exploring the possibilities of reusing oil shale ash,” Asmann states.

THRESHOLD OF NEW GROWTH

VKG is evidently a very capable partner in implementing large investments and has the technical knowledge, financial capability, and practical experience to manage complex industrial projects.

It also has well-established industrial infrastructure – heat, electricity, roads, railway connections, and vicinity to deep-water ports – all of which help to optimise both the timeline and capital cost of developments.

In addition, the group is located in an area that has historically been an industrial region.

“Today’s industry naturally adheres to the strictest environmental and living environment requirements, but establishing new factories and developments in a region with an industrial heritage is significantly smoother than in areas where work has to be done to start explaining what large industry even means,” insights Asmann.

The further development of large industries is a great opportunity for Estonia’s economy, one that VKG and its development projects have an important role and unique position in.

“We have the entire chain – the mine, oil plants, energy complex, logistical infrastructure, and an international client base,” he acclaims.

“This means we have a stable core activity, an experienced team, and a region where industry is a natural part of everyday life. It’s a strong foundation on which we are building a forward-looking business strategy.”

VKG has therefore clearly positioned itself on the threshold of new growth.

The production of bioproducts, a new mine to ensure raw material supply for decades, wind farms to add renewable energy to its portfolio, and carbon dioxide reduction projects – these are concrete developments moving to the investment decision stage.

“All of these projects are based on the industrial foundation of Ida-Viru County – the functioning infrastructure and export structure, experience, and competence.”

STRATEGIC GOALS

Of VKG’s strategic goals, the security of raw material supply and development of new business areas beside shale oil are the most important.

By the end of this year, it will finally achieve the capability to launch the new mine at maximum capacity and initiate the smooth transfer from the Ojamaa mine both technically and in terms of labour, with risks well under control.

“We will also complete the reconstruction of oil production units, meaning we can work with well-maintained equipment for the next five years,” he adds.

In the development of new business areas, the bioproducts plant is a key priority where the engagement of a strategic partner and initiation of the design process are critical benchmarks.

“In the short-term, we want to produce approximately 685,000 t of oil products in 2026 and do it safely. As our product is a commodity and the price is shaped in the global oil market, our financial goal depends on our ability to produce as efficiently as possible,” Asmann concludes.

“We would also like to contribute to national economic and climate policy issues. I personally contribute to the public discussion as the Chairman of the Board of the Estonian Chemical Industry Association and a member of the council of the Estonian Employers’ Confederation.”