Delta Food Industries has only been operational for four years but has already embarked on a series of significant expansions over the course of its tenure; the latest two comprising significant openings of its new dairy plant and the subsequent unveiling of a new can manufacturing unit.

Epitomising the unlimited opportunities in the Middle Eastern region for entrepreneurial thinking and proactive investment, the Company has long made a name for itself as a forward-thinking pioneer in the free zone food import market and is now making great strides to capitalise on a strong first four years of operation inside the SAIF zone.

With products traditionally ranging across tomato paste, tomato ketchup and milk powder since 2011, the 9,000 square metres of space inside the Sharjah Airport International Free Zone has turned into a centre of innovation and ideas in 2015 and 2016, and has manifested in a goal of increased capacities and an enhanced products range.

“In the last quarter of 2014, Delta Food industries FZC had invested AED 40 million in expansion of its new factory; a dairy plant for manufacturing evaporated milk and cream, while also purchasing the adjacent premises and facilitating it with new machinery,” says Mr. Shiraz Osman, founder and Chairman of Delta Food Industries. “The new plant will manufacture evaporated milk and cream. The production machinery is the latest available in the industry and it is capable of producing 250,000 cartons a month.”

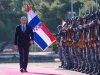

“We welcome Delta Food Industries’ new initiative,” added Saud Salim Al Mazrouei, director of SAIF Zone and Hamriyah Free Zone Authority while unveiling the new site in February, 2016. “It is pleasing to see more manufacturing units flocking to SAIF Zone, which is surely a sign that we are progressing. I hope that this initiative will enable Delta Food to offer its products locally and regionally and expand its network.

“Customers, both existing and new, are already aware of the new products and look forward to purchasing everything from one supplier rather than shopping around for different products from different suppliers.”

The next stage of growth

Delta’s portfolio of products in different sizes is consequently one of the largest in UAE to this day; the second largest food manufacturing Company in the country all-told.

A production capacity of four containers a day across any of its market-leading products compounds this rapid development and is now being supported by Managing Director (MD), Mr Ali Parpinchi’s future vision of introducing even more products into the Delta Foods remit.

Tuna, butter, yoghurt and cheese are all on the agenda, meaning that – with an export rate already more than 300 containers a month across a distribution network of more than 20 countries in the GCC, Middle East and Africa – a stronger internal structure is vital; capitalising on the continuous support and infrastructure that the SAIF Zone provides companies like Delta Foods.

“We are capitalising on the first four years of operation inside the SAIF Zone, with our latest initiatives enhancing our capacities as well as the range of products,” the MD noted. “We are now entering the next stage of our growth and are going to further increase our portfolio of products over the next two years.”

Industry leader

This next stage has not taken long to reveal its next strategic move either with the SAIF Zone announcing that Delta Food Industries has invested in a new can manufacturing unit to the tune of 5,000 square metres.

In the presence of Al Mazrouei, an agreement was signed by Osman; as well as Mr. Safdar Khatri and Mr. Sharad Anand, CEO of Anand Tin Containers.

“We would like to thank SAIF Zone for their road show in India which encouraged Mr. Sharad Anand to come here for the opening of the Can factory and for founding Delta Food as its major customer,” Osman stated. “They immediately decided to erect a dedicated can manufacturing unit to fulfil Delta’s requirement.”

Delta decided to enhance its vertical integration as its consumption of cans continued to increase through the addition of new product lines, and indeed in conjunction with the new dairy plant.

“Mr. Sharad Anand brings with him vast experience and technical knowledge of can manufacturing in addition to his expertise in marketing and advertising,” Osman continued.

Anand will utilise such expertise in introducing a complete packing solution to the Company; not only satisfying can demand but also PET bottles and tetra packs.

This aggressive plan for the domestic retail market in the UAE will ensure that Delta can cope with more brands, and manufacture a better quality of product across the board; compounded by an initial, extensive marketing campaign.

“The new can manufacturing unit will initially start with a capacity of 30 million cans a month before we also get into the packaging of canned vegetable and fruits, flavoured milk and protein powder,” Anand said. “The partnership will make Delta a leader in the food industry within two years.”