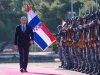

Greg Smith, President of Mada Gypsum Company, discusses his firm’s competitive advantage within Saudi Arabia.

WINNING THE RACE IN KSA

Leading from the front is challenging.

However, doing so provides significant rewards, particularly in manufacturing.

Mada Gypsum Company (MGC) has the widest production range of any building material manufacturer in the Kingdom of Saudi Arabia (KSA) with a production capacity of 42 million metre-squared (m2) of plasterboard, 168,000 tonnes of plasters, 2.9 million m2 of laminated gypsum ceiling tiles, and 7,200 tonnes of metal profile. MGC has significant production capacity of Gypsum Renders, French Molding, French Adhesive and Jointing Compound. As such, President of the firm, Greg Smith, believes his firm’s competitive advantage is clear to see. “Without a doubt it is simply MGC’s leadership in developing and growing the industry in KSA,” he stresses. “We were the first large scale producer of drywall in KSA. MGC has from the outset focused on supplying and selling drywall systems and we are the only one of the seven local producers that have fully tested and third party certified all the systems we sell.”

Smith has been involved in the industry throughout his entire career from working as a tradesman in Australia to training installers on the KLCC towers in Malaysia. He subsequently moved into technical sales with Lafarge/Boral and ran the technical sales across 10 countries in Asia.

“After working in Asia, I moved to India to set up a Greenfield drywall metal manufacturing business working with some of the country’s leading developers such as Oberoi group, the Panschil group and Lodha on their projects,” explains Smith. “We were instrumental in leading the way to introduce drywall into the hotel and hospital segments and secured the Mumbai airport project. Taking up a role with the leading gypsum manufacturer in the Middle East was a simple decision.”

Established in 2005, Mada Gypsum Company was formed in Yanbu in KSA. MGC takes a system-oriented approach by providing high-quality products, services and internationally certified systems. The company has established itself as an influential name in the GCC region and has a significant presence in Levant, Egypt, Africa and the Indian subcontinent. In order to achieve such considerable dominance in the market, Smith believes that MGC has assembled the best and most knowledgeable manufacturing team, while having the most technically capable sales team too.

“Our ability to supply the complete range of drywall products, produced and certified according to international standards complemented with the best people allows MGC to be renowned as one of the market leaders amongst the multinationals present in the region,” Smith tells us. “Combined with our fast moving and innovative approach, this gives us a real point of differentiation and this in turn leads to MGC supplying the best and most complete range of drywall products in KSA, allowing us to compete directly with the multinational players.”

SUSTAINABILITY DRIVE

Mada Gypsum Company places significant value on its sustainability drive. In fact, through the company’s filtration system, water wastage is zero.

“We value environmental protection and ensuring the health of our planet for future generations,” discusses Smith. “Sustainability is very high on our agenda, our factory outputs either air, solid or liquid waste are monitored and controlled by our industrial governance which in MGC’s case is the Royal Commission. We sell our recyclable waste, recycle our own waste and we even use recycled water. This is from utilising desalination plants in our processes instead of using fresh fully purified water. In addition, we use original filtration systems for our air outputs as recommended by the top machine manufacturers in Europe.”

As the COVID-19 pandemic caused disruption across the world, operations halted almost overnight. However, Smith stresses that the most important thing was prioritising the health and safety of the workforce.

“We had to firstly make sure that employees had access to reliable information about the virus through trusted, official sources,” discusses Smith. “Secondly, companies all over the world have had to adapt to changed circumstances and consumer behaviours and find opportunities in times of crisis.

“This required lots of innovation, creativity and the development of new business models. We looked to increase our cost efficiency, such as obvious ones like business travel reduction and moving to online meetings, we also looked at internal projects that could be paused or stopped.”

“The most important success factor in any business is the people!”

Greg Smith, President, Mada Gypsum Company

DIGITALLY DISRUPTING MANUFACTURING

The manufacturing industry is at the forefront of change and has transformed significantly in the sector over the past few years. In order to stay ahead, companies such as MGC must be proactive in the market and seek to leverage innovations that adds value.

“The technology is continuously changing due to the world needing alternative sources rather than using natural resources,” says Smith. “Examples are the use of recycled gypsum and by-products (waste from other industries) to be used as raw gypsum replacement. Also, the world of technology is focusing on making products, simpler, lighter, and more efficient while reducing the loads on the planet. We are always searching for new alternatives, some are feasible, and some are not due the economy of scale not yet being fully matured in these new alternatives. We continue to monitor these new developments and have them under continual study.”

PEOPLE-CENTRIC

Talent management is an essential component to all successful companies. Ultimately, people are the heartbeat of all companies, and it is Smith’s belief that the company’s staff are the key drivers to success.

“I believe the biggest motivation to people is that we hired these people to tell us what needs to be done and give them the freedom to think and execute their thoughts rather than only asking them to execute our thoughts,” discusses Smith. “Like Steve Jobs once said, ‘It doesn’t make sense to hire smart people and then tell them what to do: we hire smart people so they can tell us what to do.’ I believe that this is the ultimate provision of empowerment and motivation. At MGC, we practice a friendly working environment, in addition to having good award systems in place.

“The most important success factor in any business is the people! Having the right people in the right places is very critical. At MGC, our approach in talent acquisition is through utilising our community service, by having summer or cooperative trainees we can assess their fit to the position prior to the recruiting along with the other process of recruiting. In addition, empowering employees is exactly why we have an open-door policy where anyone can take up their discussion to the management when it’s needed whether it’s the operation director for instance or even the president. Finally, here at MGC every month a lunch is organised for all employees as a way of giving back to our team and showing our appreciation.”

“The world of technology is focusing on making products, simpler, lighter, and more efficient while reducing the loads on the planet”

Greg Smith, President, Mada Gypsum Company

FUTURE PLANS

Looking ahead, Smith’s priority for the coming years is to position itself as the partner of choice for its clients while organising itself to match the requirements of its clients.

“In respect of our retail/distribution customers we have a dedicated, highly knowledgeable team of experienced and long serving employees working closely with our partners to help them win business. In the case of the project marketplace, we have a substantial technical and design team who not only help in the initial design but are also active at site working closely with contracting design teams to ensure we deliver specification and aid with value engineering. Our geographically based project engineers work with clients to ensure that our agreed solutions are delivered on site which ensures that our contractor partners deliver their clients’ required specification in the most efficient way.

“Our goal is to add value to our clients’ operations, whether that is helping our distribution partners grow their business or our design and technical teams working in partnership with our contractor clients to design solutions that achieve demanding build specification and deliver efficiency on site. Our expansion is focused on further enhancing our teams of specialist enabling us to work even closer with our clients. All of the above is underpinned with substantial IT investment to give us the tools required to support our immediate requirements and substantial future growth plans.”