Championing the use of aluminium packaging, Moravia Cans continues to produce cost-effective, cutting edge aerosol products for clients all over the world.

THE ALUMINIUM ADVOCATE

Infinitely recyclable and extremely durable, almost three quarters of all aluminium ever produced is still in use today.

It is believed that around 900 million tonnes of aluminium have been made since 1880, with the majority now sitting in buildings, electrical cables, machinery and within transport applications. Recycling all of this would equate to 17 years’ worth of current annual aluminium production.

It is a marvel of a metal. 100 percent reusable and able to indefinitely retain its properties, aluminium has rightly become the poster child of sustainable packaging solutions, commonly dubbed the most valuable item in the recycling bin.

For Martin Boaler, it represents the true definition of recyclability.

“Recycling should mean you can return your product and have it reused or remanufactured as the same product again, and again, and again,” he says. “This is not downcycling where the material is used for something less and less valuable and loses some performance each time until it reaches landfill or incineration.”

Boaler is a packaging industry veteran. An engineer and chartered accountant by trade, he now serves as Managing Director of Czech Republic-based Moravia Cans, specialist producer and global supplier of aluminium aerosol containers.

The introduction to Moravia was an unconventional one, with Boaler originally trying to buy the company whilst serving as Head of Mergers and Acquisitions at Impress Group, now part of Ardagh Group. Having stayed in contact with the owners, he accepted an approach to join and lead the company in early 2017.

LOW COST, LEADING EDGE

Moravia produces around half a billion cans a year, a marked increase since the Novak family acquired the business shortly after the Velvet Revolution swept the Czech Republic in 1989, switching the focus to aluminium aerosol cans and away from aluminium tubes.

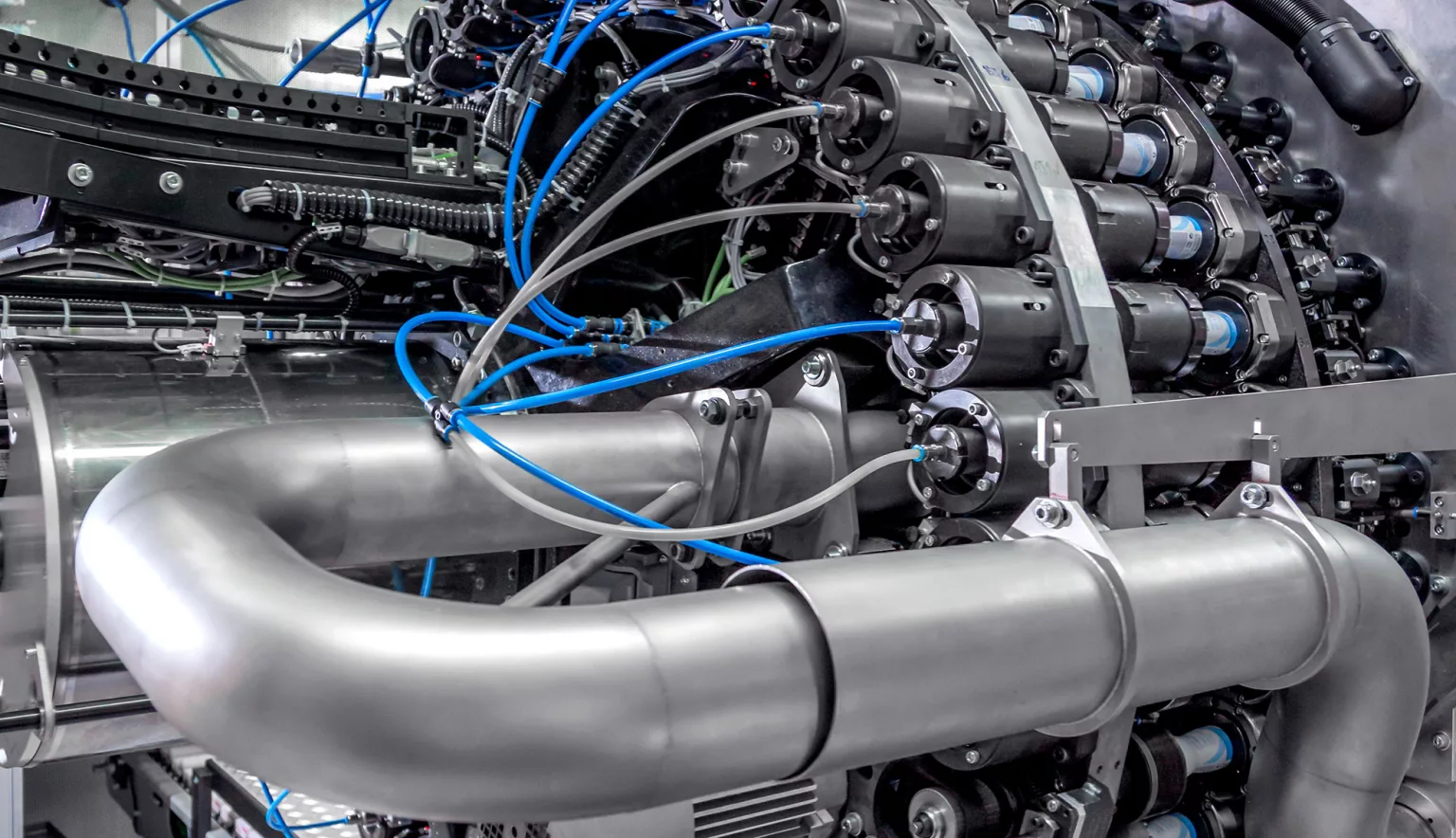

Today, from its site in Bojkovice in the southeast of the country, Moravia operates 10 production lines, using both the Impact Extrusion process and the DWI (Draw and Wall Ironing) process, more often associated with beverage cans.

“Moravia has a very clear USP and it may come across as a slightly surprising one,” says Boaler. “The Czech Republic has historically provided a high quality, low cost manufacturing base, and this is undoubtedly a factor behind our entry into the market.

“However, what differentiates us and sets us apart is the position we have built as a technology and product innovation leader, with the lowest material content providing the highest product sustainability. This is not always associated with low-cost manufacturers but has been Moravia Cans’ focus for a long time.”

Indeed, Moravia Cans has pioneered the full body shaping of aerosol cans, being the first manufacturer to shape the entire can from top to bottom.

“We have led the way in can forming technology,” adds Boaler, “which has led to increasing the fundamental strength of the cans, meaning our products like-for-like can be significantly lighter and more sustainable than our competitors’.”

Boaler cites the example of Unilever’s Dove, one of the many global brands for which Moravia produces cans. Using the DWI production process, the Dove can is 20 percent lighter than its counterparts and has scooped several awards, including the The Canmaker Magazine 2017 Can of the Year, and the award for the Most Sustainable Can innovation.

This is a result of industry-leading investment into research and development.

“We invest a higher proportion of our revenue into R&D,” affirms Boaler. “We have our own tool manufacturing facility here, which means we can develop new product designs very quickly. Moravia also has several offline pieces of shaping and printing equipment, something I believe is a big advantage for us in proving new product design.

“Our manufacturing process is continuous, with an aluminium coil or slug input at the start, running through the line and coming out as a complete can. There is almost no work in progress, and this is a very efficient unitary production process.”

Being able to produce prototypes offline minimises disruption to this manufacturing efficiency, meaning only a small amount of production line proofing is required before a new can is ready to enter production.

While being home to leading-edge machinery is undoubtedly crucial to remaining ahead of the industry curve, Boaler also pays tribute to Moravia’s skilled employee base who are responsible for maximising the benefit of such technologies.

“At the moment we have over 450 employees, and their training and development is critical to us,” he adds. “The Czech Republic has a strong education system with some excellent graduates joining our workforce. We are a very young team for the industry, which provides a very solid base for the future.

“While it is becoming harder to attract people as the economy here has developed, I believe the quality of our operation, and the fact we have grown up with the country does make a difference.”

The company also works with an international network of suppliers for all grades of aluminium, a supply chain which reflects the global nature of the business.

SUSTAINABLE DNA

This includes aluminium used in Moravia’s Impact Extrusion and DWI products, with another focus of the company’s R&D activity being the increased application of alloyed input material including elements such as manganese, magnesium and zirconium.

“The alloys help the product to retain strength once it has gone through the various heating and deformation processes that are necessary to both coat and shape the product,” says Boaler. “This provides the best strength retention to enable our weight and cost reduction.”

The introduction of proprietary patented super alloys underlines the notion that sustainability is etched into Moravia’s DNA.

“A guiding principle has been the desire to produce the most shaped, brand identified cans possible, and at the lowest cost. This requires the best printing and the best shaping machinery and processes to enable complex products to be produced as quickly and affordably as more standard products,” Boaler continues.

“We can form complex cans at the same speed as standard cans, and at the same time we can optimise the weight, making them lighter and more sustainable. This has always been in our DNA.”

Conversely, it is Boaler’s job to ensure Moravia remains at the forefront of sustainable packaging development and fulfils its remaining capacity at Bojkovice, which the MD states can be expanded by another 35 percent as new developments continue to come on stream.

“Compared to 2014 we are supplying 50 percent more product,” he states. “It is a very promising growth rate and we are focused on maintaining that growth in the years to come.

“There will be a point at which we have to look beyond our single site approach and may have to consider organic or inorganic means of expanding on this, but that is at least a year or two down the line.”

“We have a very strong sustainability story. But we, as an industry, must continue to look at reducing the fundamental amount of energy and material needed to make packaging. Our story is an impressive one so far in terms of 100 percent recyclability and continuous lightweighting, but it is by no means over.”

Editor’s note: Many of the business leaders featured by EME Outlook continue sharing their insights on LinkedIn. For CEO’s across EME seeking to strengthen their online presence, visit LinkedIn for CEO’s.